Opis izdelkov

PB series press brake features a rigid frame for minimum deflection under the load. The frame steels are German origin, ultrasonic controlled & ST-44 material. Machine welding is made by welding aparatus & welding robots. After the welding, we make stress relief process by vibration system. After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy,. All reference surfaces and connection holes are machined. By all this processes machine frame sensivity is protected for a long life time.

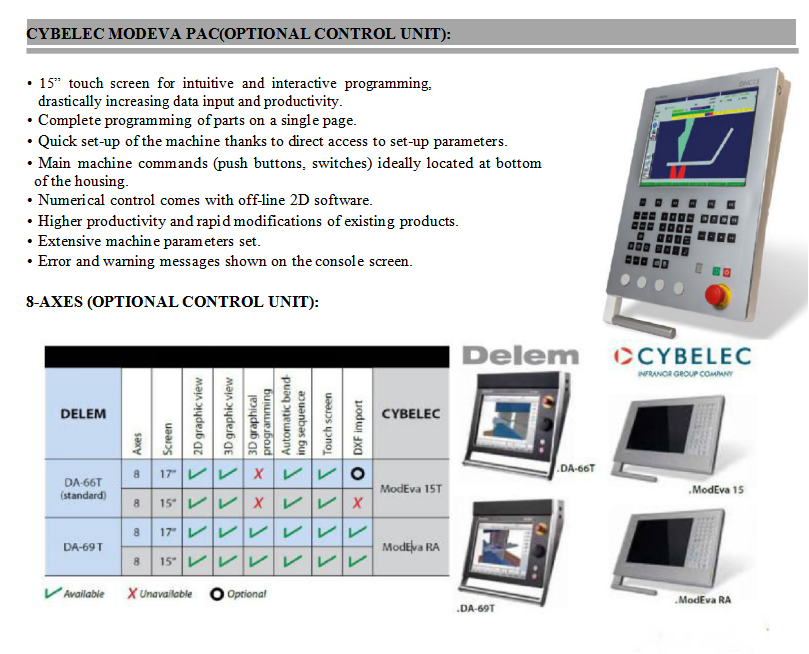

CNC control system

1. Hitro, enostransko programiranje

2. Navigacija s hitrimi tipkami

3. 7" širokozaslonski barvni TFT

4. Up to 4 axes (Y1, Y2, and 2 auxiliary axes)

5. Kontrola kronanja

6. Knjižnica orodij/materiala/izdelkov

7. USB, periferni vmesnik

8. Advanced Y-axis control algorithms for closed

9. loop as well as open loop valves10.Panel based controller with optional housing

Slike s podrobnostmi

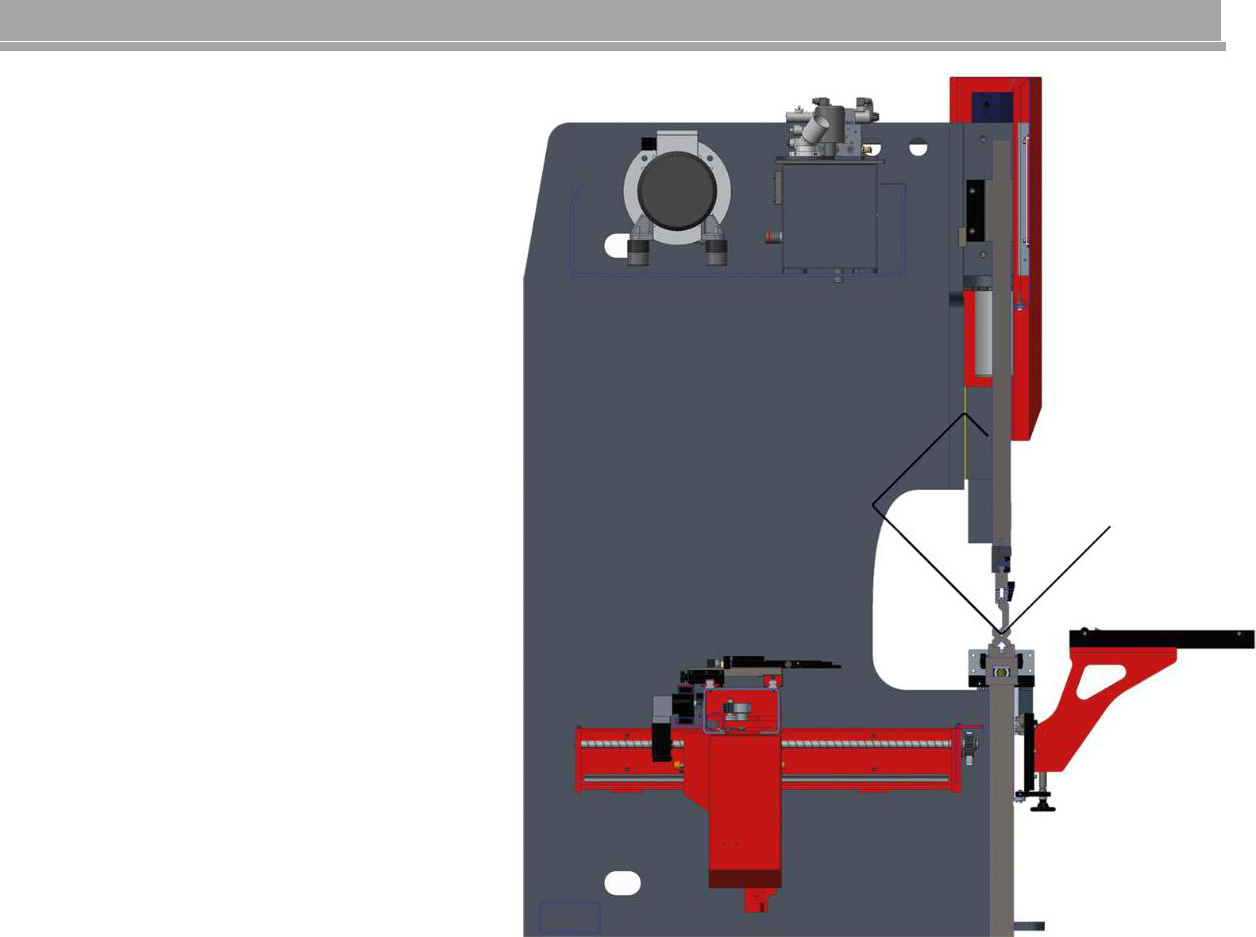

Side Looking:

Side Looking:

The large openings and strokes of the WC67K Series facilitate the versatile production of parts requiring increased clearance to profitably and easily produce. This includes but is not limited to the production of deep sectioned four sided boxes. This provides for more clearance when bending parts with larger flanges. In some cases this allows the buyer to purchase a smaller overall bend length press brake, a cost savings, as this large clearance allows large flange bending on the overall bend length dimensions of the machine.

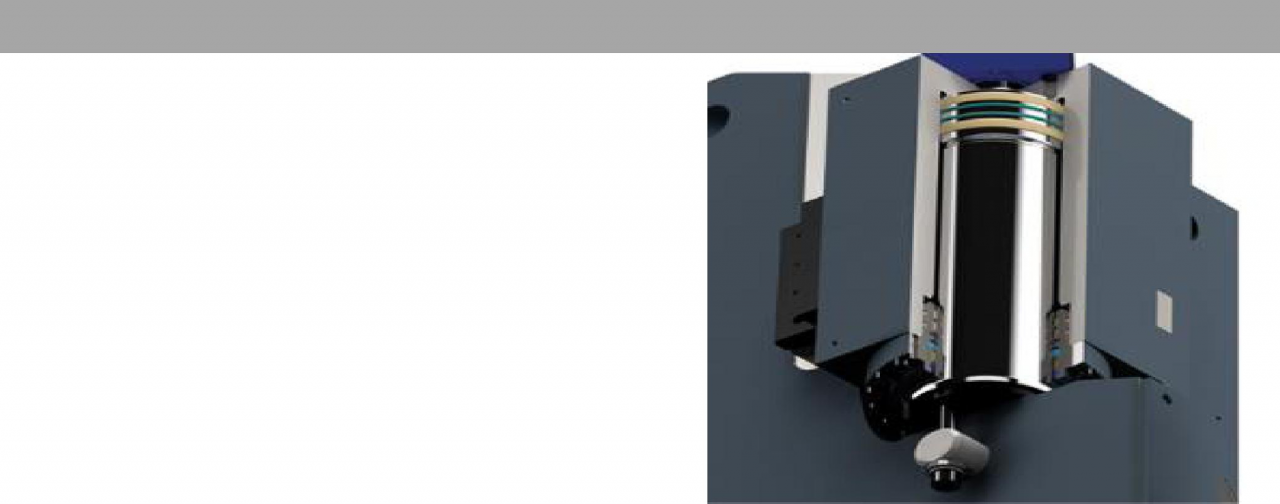

MACHINE CYLINDERS

In order to allow tilting of the ram without damage,because we use spherical connections.

This type of connection also allows peak forces to be absorbed gently.

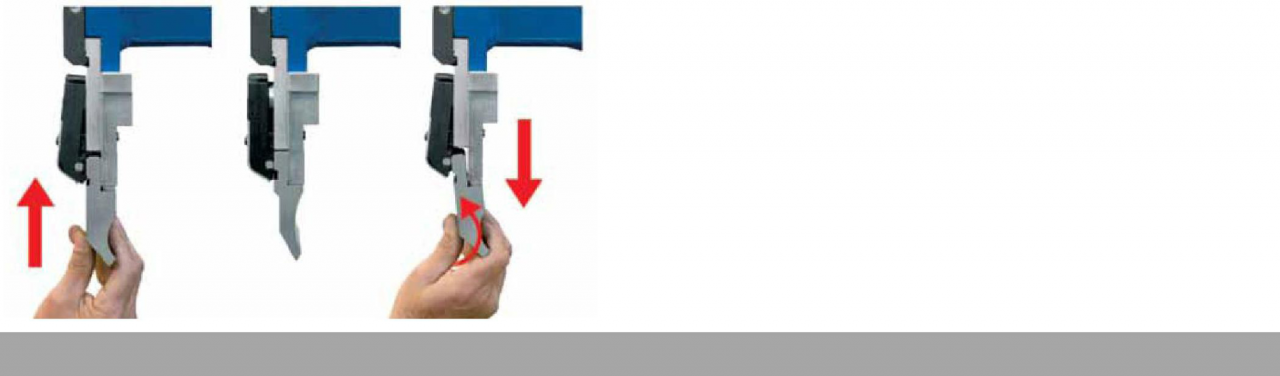

SPEED GRIP SYSTEM

The speed grip system reduces the time spent changing tools by 8.5 times compared with traditional systems.

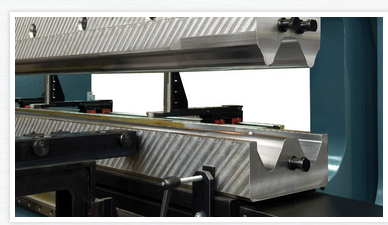

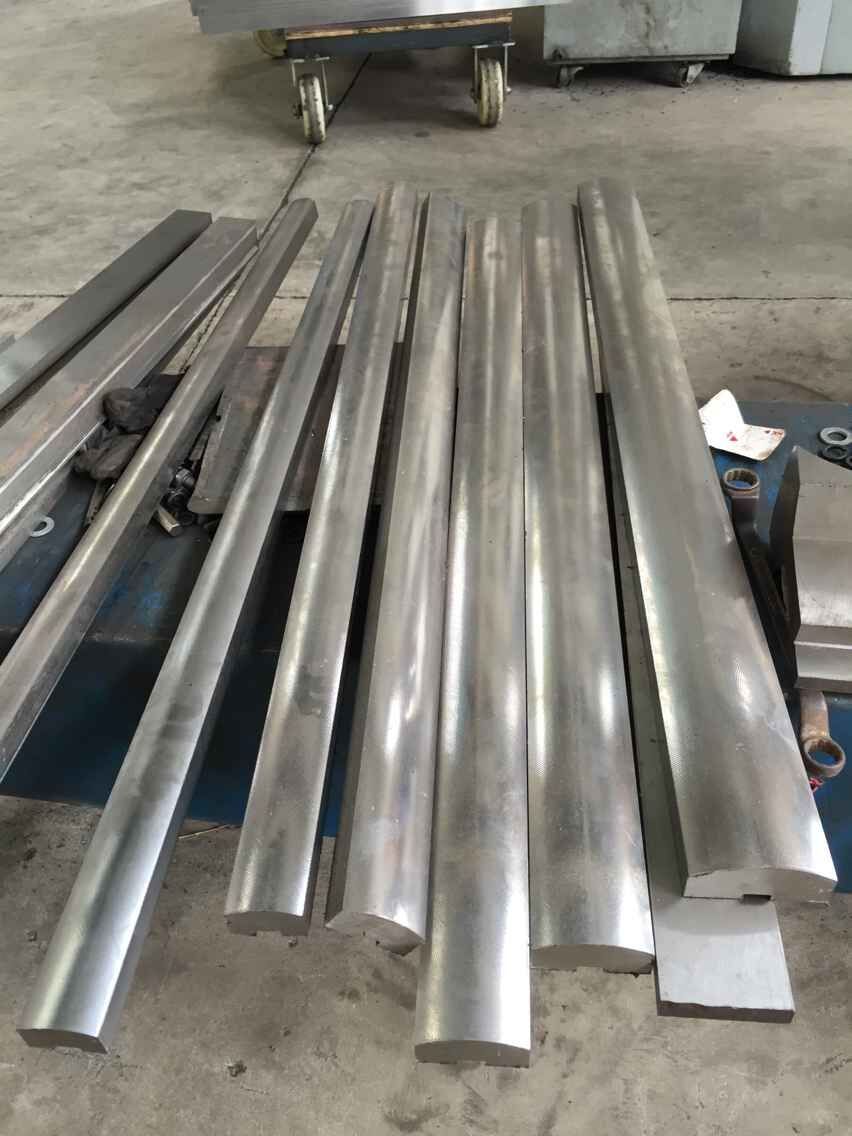

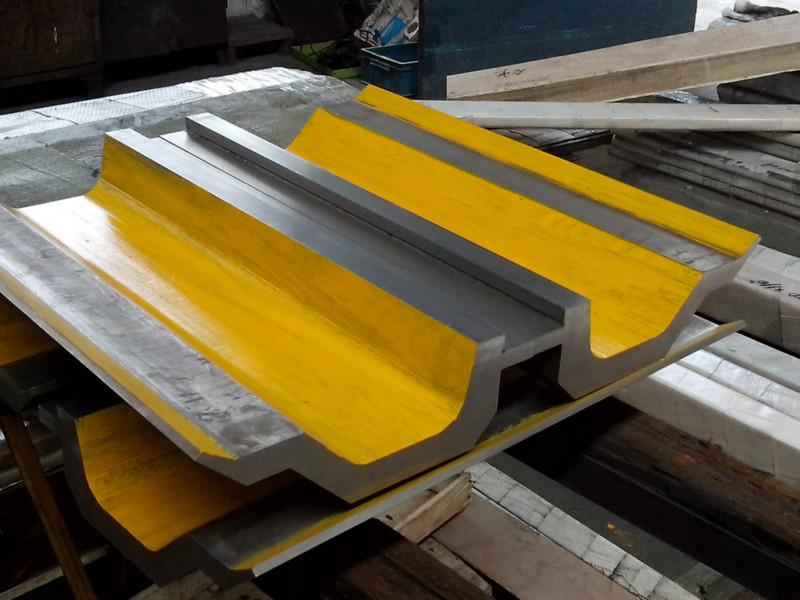

TOOLING

Large selection of tooling, dies and parts in stock and ready to ship, including goose neck, standard style, american style, & european style tooling; 4 way press brakes dies, multi V dies, quick clamps, back gauges and more.

Laser Safety Systems

* Innovative tooling grid guarding pattern

* Completely foot peddle controlled operation

◦box-shaped part bending feature

◦Type 4 patented process control

◦Innovative safety technology

◦automated tooling calibration.

◦Bending a box without eliminating or reducing the effectiveness of the safety system.

◦Minimum slow speed way when bending flat material by special arrangement of the laser beams.

◦Additional machine monitoring (emergency stop buttons & gate interlock switches)

* CE Certified Category 4 Safety Controller with integrated force guided relays and encoder feedback system.

Machine mould :

Podrobnosti

- Hod drsnika (mm): 120 mm

- Samodejna raven: popolnoma samodejno

- Globina grla (mm): 220 mm

- Tip stroja: Sinhroniziran

- Dolžina delovne mize (mm): 2500 mm

- Širina delovne mize (mm): 120 mm

- Dimension: 2500*1300*2210

- Stanje: Novo

- Kraj izvora: Anhui

- Material / obdelana kovina: medenina / baker, nerjaveče jeklo, zlitine, ogljikovo jeklo, aluminij

- Avtomatizacija: avtomatska

- Dodatne storitve: Rezanje na dolžino

- Teža (KG): 4000

- Moč motorja (kw): 5,5 kw

- Ključne prodajne točke: avtomatsko

- Garancija: 2 leti

- Veljavne panoge: trgovine z gradbenim materialom, delavnice za popravilo strojev, proizvodni obrat, domača uporaba, gradbena dela, energetika in rudarstvo, oglaševalsko podjetje

- Lokacija razstavnega prostora: Brez

- Vrsta trženja: Nov izdelek 2021

- Poročilo o preskusu strojev: priloženo

- Video odhodni pregled: priloženo

- Garancija na osnovne komponente: 2 leti

- Core Components: Bearing, Motor, Pressure vessel

- Certifikat: ce

- Zagotovljena poprodajna storitev: brezplačni nadomestni deli

- Product name: WC67K 125T/2500mm

- Type: PB

- Uporaba: upogibanje nerjavnih plošč

- Control system: DA52S

- Bending length: 2500mm

- Nominal Pressure (kN): 1250 kN

- CNC Control system: CNC